Motor- and spring-driven cable reels are designed for the power supply to movable machines. The motor- and spring-driven cable reels are manufactured in accordance with the travel distances and the power of the movable machines. Regarding the version of the cable reel it is differentiated between cylindrical and spiral version. Which one of these versions is chosen depends on the customer’s resp. design-requirements.

Special designs and the required accessories are innovatively produced by STEMMANN-TECHNIK corresponding to the customer’s requests.

Enquiry : Spring Driven Cable Reels | Motor Driven Cable Reels

-

Overview

Spring-driven cable reels serve for the controlled reeling on and off of cables, hoses or ropes – mainly for cranes, stacking devices or in waste water technology. Driven by means of spiral leaf springs they present a well priced alternative with regard to the motor-driven cable reels – especially for movable devices without internal power supply. Depending on the customer’s requirements spring-driven cable reels of STEMMANN-TECHNIK are produced in cylindrical or spiral version – normally with slipring assemblies for power- and data transmission, if required they are also produced as hose reel with rotary joints for different media.

-

TLF123

The picture shows a spring-driven cable reel of series 123 with an 8-poles-slipring assembly for 10 A. Technical Data:

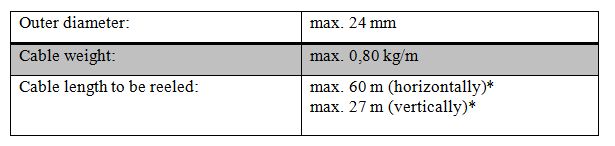

Cable Data:

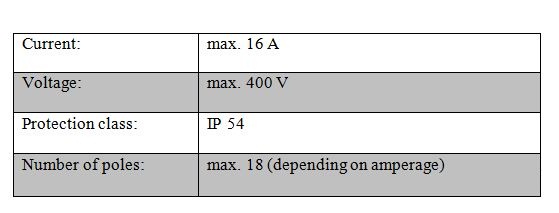

Slipring Assembly Data:

-

TLF190

The picture shows a spring-driven cable reel of series 190 with a 4-poles-slipring assembly for 25 A, an additional return movement locking and laid on cable. Technical Data:

Cable Data:

Cable Data: Slipring Assembly Data:

Slipring Assembly Data:

-

TLF280

The above picture shows a spring-driven cable reel of series 280 with a 7-poles-slipring assembly for a current transmission of up to 25 A.

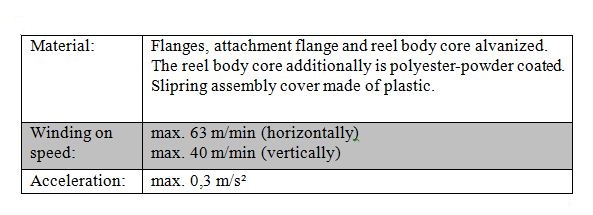

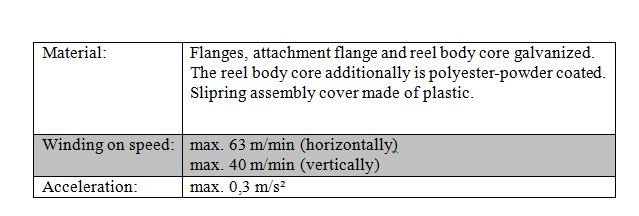

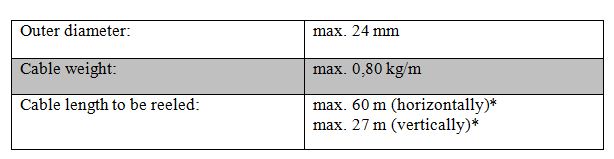

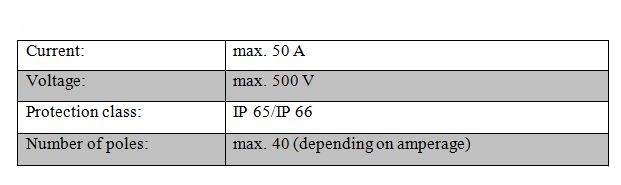

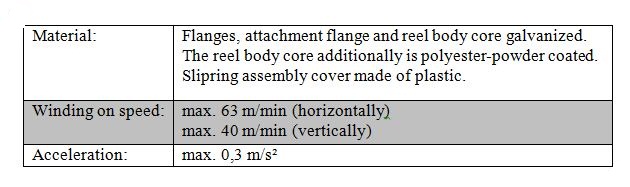

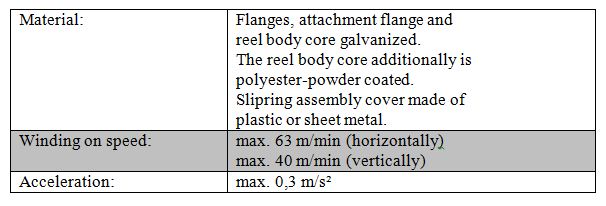

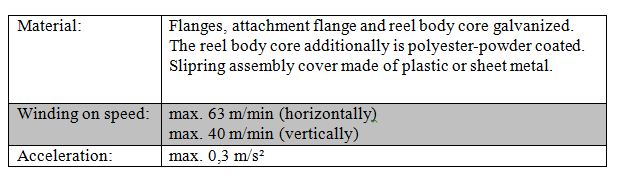

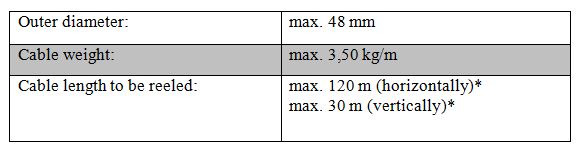

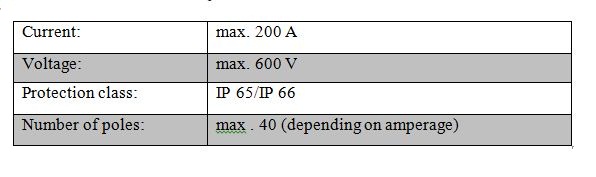

Technical Data:

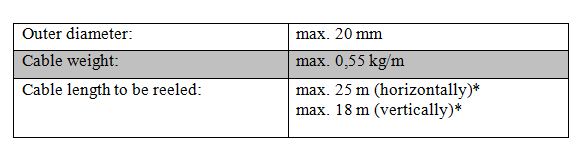

Cable Data:

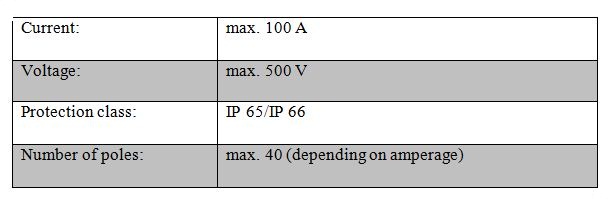

Slipring Assembly Data:

-

TLF300

The above picture shows a spring-driven cable reel of series 300 with a 40-poles-slipring assembly for data and control signals.

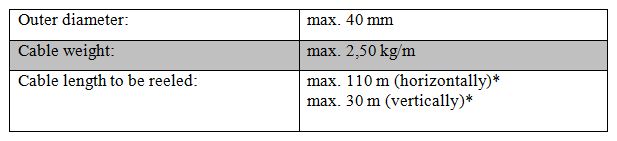

Technical Data:

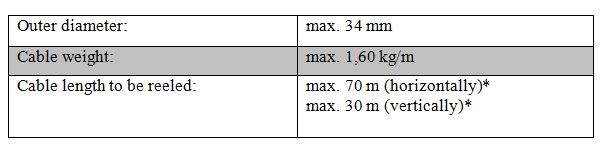

Cable Data:

Slipring Assembly Data:

-

TLF400

The above picture shows a spring-driven cable reel of series 400 with a 14-poles-slipring assembly for 20 A as well as a complete polyester-power coating and additional cable gland inside the attachment flange.

Technical Data:

Cable Data:

Slipring Assembly Data:

-

TLF500

The above picture shows a spring-driven cable reel of series 500 with a 5-poles-slipring assembly for 100 A.

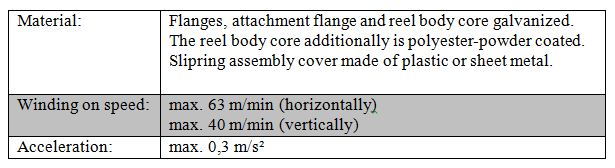

Technical Data:

Cable Data:

Cable Data:

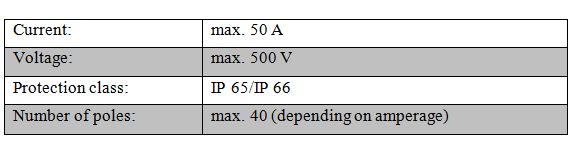

Slipring Assembly Data:

-

TLF600

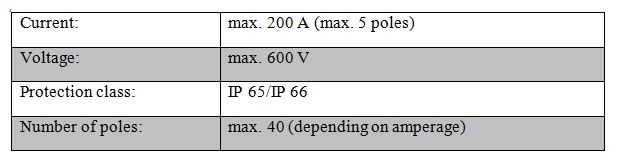

The above picture shows a spring-driven cable reel of series 600 with a 4-poles-slipring assembly for 200 A and a sheet metal-cover.

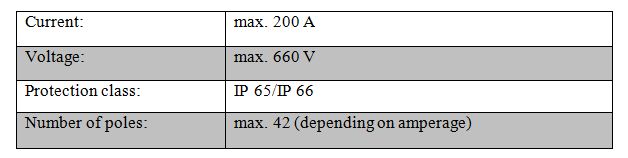

Technical Data:

Cable Data:

Slipring Assembly Data:

Movable machines, first of all several types of cranes, as container bridges or indoor-cranes, several batch plants and large open-cast mining-devices but also longitudinal reamers in purification plants and sliding platforms realize the current- and data-transfer by means of flexible energy- and control cables.

Maintaining the transmission requires a permanently available system for storing and releasing the cables which moves as synchronous as possible with the movable machine. The basic patterns of the movement – distance, direction, acceleration, speed, mass – are being defined only by the use of the movable machine.

Systems which meet such requirements are the motor driven cable reels.

Motor cable reels consist of reel body, drive and slipring assembly as described in the individual chapters of this catalogue. Depending on the concrete application case, the recommendations for different accessories can be made.

Besides the current transmission STEMMANN-TECHNIK, upon request, realizes the transmission of different media, e.g. water resp. argon or other gases.

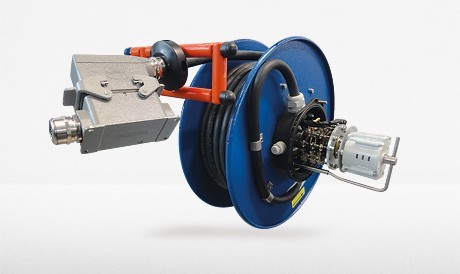

We provide very compact fibre optic rotary connectors, which have proved themselves when using optical fibre lines in combination with electrical power transmitters.

We provide very compact fibre optic rotary connectors, which have proved themselves when using optical fibre lines in combination with electrical power transmitters.

Owing to its small outer dimensions, the rotary connector is particularly suitable for use on spreader cable reels, as well as stacking cranes and railway cranes. It is resistant to vibrations.

10 years of zero maintenance operation from our fibre optic rotary connector can be assumed.

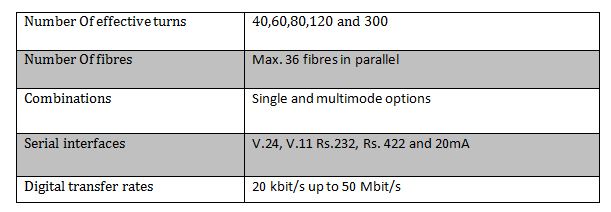

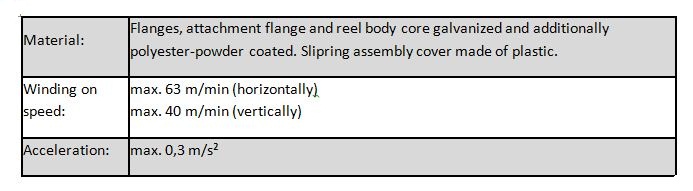

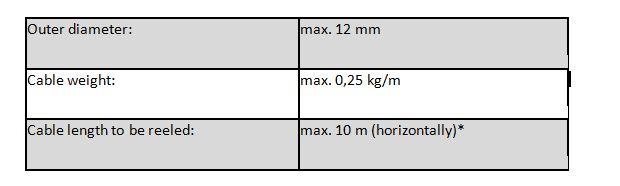

Technical Specification: