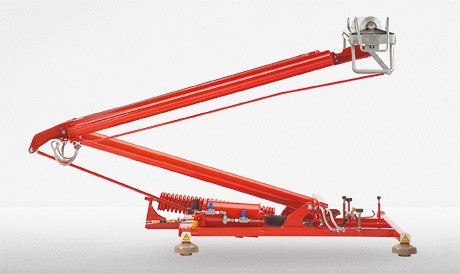

Roof-mounted pantographs for tramways, trains, special vehicles, suburban railways, metros, traction units (EMUs) and locomotives are developed for different overhead line-systems and speeds, whereas the raising to and lowering from the overhead line is realised by an electrical or a pneumatic drive acc. to customer’s requests.

The continuous contact force to the overhead line at higher speeds is realised either by mechanical aero foils or by an especially developed electro-pneumatic control. If requested an emergency dropping device is quoted which lowers the pantograph as quickly as possible at collisions with the overhead line.

The Fb 700 series has been deliberately designed with a small number of individual components and guarantees a low weight and very low maintenance costs. The Fb 800 unifies all the advantages of the Fb 700 and combines them with a high-strength upper arm of steel and a collector head that is movable in the direction of travel with a maintenance-free spring design.

TECHNICAL SPECIFICATIONS:

Our DSA roof-mounted pantographs have been developed for high performance in heavy rail systems (Heavy Rail Vehicles). Their design concept, with high-strength, lightweight and innovative engineering has proven itself worldwide under the most difficult conditions.

DSA pantographs can be designed for AC and DC overhead wire networks and reach operating speeds of up to 380 km/h.

DSA 150

Single-arm pantograph for tough daily use. The pantographs are available in modular construction with collector head widths of 1450 mm, 1600 mm and 1950 mm for use in different countries.

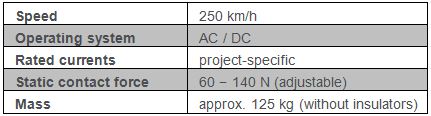

DSA 200

Single-arm pantographs for general daily use. The pantographs are available in modular construction for use in different countries.

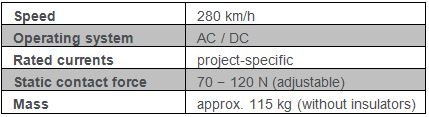

DSA 250

Because of the low mass of the collector head, the DSA 250 has good dynamic properties. As a result, it is very well suited not just for single traction and double traction, but also for multi-traction.

DSA 350

The optimised joint kinematics and the good dynamics, owing to the small masses, allow problem-free use of the pantograph in overhead wire networks.

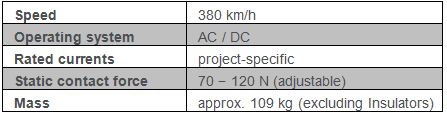

DSA 380

Single-arm pantograph with small collector head masses and excellent aerodynamics for use on modern high-speed routes. They are perfectly suited for single traction, double traction or multi-traction. They can be optionally fitted with an automatic lowering device and a mechanical raising height stop.

-

Open-Loop-System

In order for the electrical energy to be transferred from the overhead wire to the rail vehicle without any interruption, the pantograph must touch the overhead wire with the same contact force at all speeds. Too little contact force can lead to interruptions; too much would result in increased friction – and hence increased wear. The electro-pneumatic controller of our Open Loop System ensures an uniform contact force of the pantograph on the overhead wire at all speeds. All the pantograph types of our DSA series can be subsequently optimised by this system.

System advantages:

- Increasing the speed on older tracks

- Improved contact quality

- Less arcing

- Less wear

- Reduction of the noise level

- Reduced measurement and optimisation cost

-

Non Icing System

Icing of overhead wires in railway systems is a recurring problem in the winter months, since ice formation on the overhead wires impedes the transfer of electricity over the contact strips. The resulting damage can involve enormous costs. To ensure troublefree operation even at extreme temperatures below zero and to prevent icing, we offer a highly effective system through which the overhead wires are coated with an antifrost in advance. The operating equipment costs for this preventive non icing system are very low. The system consists of two components – the main system that is installed inside the railway coach, and an additional roof-mounted pantograph, whose collector head is replaced by a lubricating device with a felt roll. System advantages:

- Operational shutdowns of passenger services (overhead wire, wagons) are significantly reduced

- Damage to the electronics of the wagons owing to contact interruptions are avoided

- The carbon brush wear is reduced

- Owing to the secured contact of the contact strips with the overhead wire, the wagon is provided electrical energy continuously

-

ADD − Automatic Dropping Device

Damaged pantographs can have seriously effects on the operation of the wagon and result in economic losses for the route operation. For example, if multiple-unit trains run with damaged contact strips over several kilometres, this will normally cause damages to the over head wires. This is why we have developed an automatic emergency lowering device (Automatic Dropping Device). As an alternative to the mechanical quickdropping by spring unlocking, we have developed the gas pressure ADD system for LRV pantographs in suburban rail systems. The quick dropping with electric drive is based on a compressed gas unit. The system essentially consists of two components, the actuation unit and the pneumatic cylinder. The system ensures that pantographs with damaged contact strips or collector heads are lowered automatically. In this manner, consequential damage to the overhead wire is reduced to a minimum. A system-side sequential circuit also causes the lowering of the following pantographs so that they are also actively protected from damage. Overall, the repair and consequential damage costs on multiple-unit trains and overhead wires can be reduced significantly by this system.