Slipring Assemblies

Slipring assemblies for energy- and data transfer are being used for all products which do not allow any stationary current supply due to their rotary movement. Thus, the applications range from current transmission at slowly moving round reamers in purification plants to explosion-proof slipring assemblies with media lead-through for oil production vessels.

The slip ring assembly, contact blocks and power transmissions for data or signaling can be configured and customized for every requirement. We can draw on a wide range of standardized series and advanced technologies to achieve the optimum technical and economical solution for each customer. Even for complex requirements and extreme operating conditions.

With our technology for slip ring systems, we cover a wide range of applications. Based on this design are worked out according to the individual wishes of the customer for the particular application and adapted to the technical requirements as well as environment-related requirements.

By continuously developing our products and the use of innovative technologies, we assure the high quality of our solutions sustainable. Improved technologies lead to more efficiency and functionality, for example by smaller designs, higher performance and longer life cycles.

Standard technologies

- Carbon / brass systems for conventional power transmission and data transmission

- PCB systems for digital data / signals or power transmission

- Molded slip rings for applications with high speed and strong vibration

- Multiwire grinding systems with multi-layer for low-noise signal transmissions

- STEMMANN TECHNOLOGY SICL10 system the single insulated conductor rail for very large / diameter concentric

-

Special – Purpose Solutions

The slip ring assembly, contact blocks and power transmissions for data or signaling can be configured and customized for every requirement. We can draw on a wide range of standardized series and advanced technologies to achieve the optimum technical and economical solution for each customer. Even for complex requirements and extreme operating conditions.

With our technology for slip ring systems, we cover a wide range of applications. Based on this design are worked out according to the individual wishes of the customer for the particular application and adapted to the technical requirements as well as environment-related requirements.

By continuously developing our products and the use of innovative technologies, we assure the high quality of our solutions sustainable. Improved technologies lead to more efficiency and functionality, for example by smaller designs, higher performance and longer life cycles.

Special resolution technology

- Carbon / carbon specially designed for extremely high speeds

- Optical Systems for the contactless transmission of signals

- High power systems for maximum performance in the smallest space

-

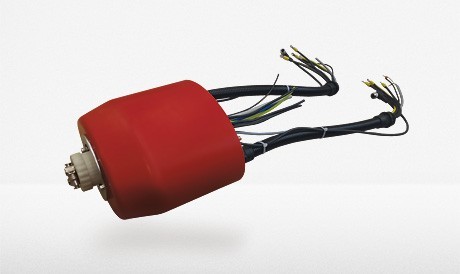

FP Series

The slipring assemblies of series “FPKK” are well-priced standardised components. The basic types for 25, 50 and 100 A are available directly from stock. Due to the consequently implemented modular system also combinations between power- and data transmission are possible.

The slipring assemblies of series “FPKK” are well-priced standardised components. The basic types for 25, 50 and 100 A are available directly from stock. Due to the consequently implemented modular system also combinations between power- and data transmission are possible.The slipring assembly housing is made of shock-proof, glass fibre-reinforced plastic. A self-regulating heater can be used optimally. Together with the high protection class of IP 66 the slipring assembly is optimally suitable for the use in rough ambient conditions.

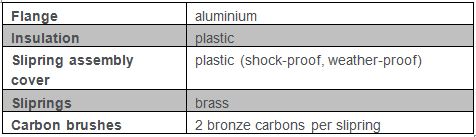

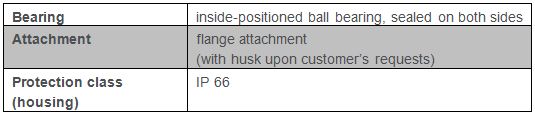

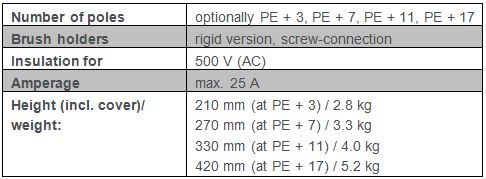

Technical specification :

Series “FPKK 54-25”, “FPKK 54-50” and “FPKK 100-100” :-

Material:

General Data:

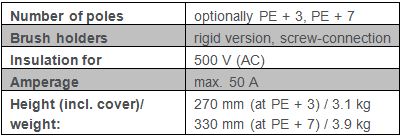

Series “FPKK 54-25”:

Series “FPKK 54-50”:

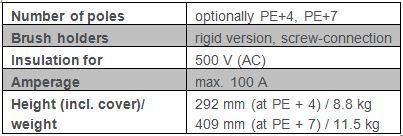

Series “FPKK 100-100”:

-

MK-Series

These slipring assemblies, used among others on excavators and round reamers, include the design series MKSR, MKSRR and MKSK. They are beared by means of spherical rotary joints and as standard effected in protection class IP 54. The outer capsulations are parted into segments to grant the accessibility during installation and maintenance.

MKSR with diameter of 130 transmit up to 100 A, at diameter of 300 up to 600 A. MKSK-versions enable currents of up to 1200 A.

Internal protection tubes of the MKSRR enable the leading through of hoses and tubes, which for example are necessary for returning mud of round reamers.Series “MKSR 200, 240, 300, 360, 400”

- installed on a spherical rotary joint

- control current part “LP60”

- control current wired on terminal strip

-

LP- series bako ®

Unlike conventional standard slip rings are “bako ® Slip Ring Assemblies’ complex structure Schleifringübertragersysteme with numerous options for customized product manufacturing.

The variety of designs ranging from low to combinations with angular encoders, media distributors and medium-voltage components (up to 30 kV).

The applications range from the power supply and data transmission for crane applications to wind energy and radar equipment.

The types of “bako ® Slip Ring Assemblies” are based on our PCB Technology:

bako ® LP103

Of variants- with holder for angle encoders, connectors,

- High-current components, etc.

- with large open-hole to 950 mm

- with integrated thermowell, media distribution, etc.

- with concentric structure with low installation height

- with kundenindividuellem housing

- (Cast aluminum, adapted to the design)

Note:- For Windmill applications related enquiry please refer to

STEMMANN-TECHNIK GmbH Germany or visit the site http://stemmann.de/ -

Explosion – proof Slipring Assemblies

For the use in hazardous areas STEMMANN-TECHNIK GmbH has developed a production series of slipring assemblies which comply with these special requirements. Versions with excess pressure- and explosion-proof housings are available. Protection classes, temperature classes and zones can be effected in accordance with customer’s specifications.

The example shown is a explosion-proof encapsulated combination of electrical power- and data transmission with an additional fibre optic rotary connector for optical data transmission.

The complete unit has a boring of 300 mm in the centre which allows an additional media lead-through.

-

Slip Ring Assemblies: Power Feed